What is Kanban? A Beginner’s Guide!

- 16 mins read

-

By Bhaskar S

- Updated on April 30, 2024

Navigate to

What is Kanban?

Kanban is a visual work management system that provides a clear representation of work progression within a process. It offers a visual depiction of both the workflow process and the tasks in transit. The primary aim of Kanban is to pinpoint any possible obstructions in your process and resolve them, enabling work to move efficiently at an optimal pace, thus ensuring cost-effectiveness.

TRIVIA – Kanban, also spelt “kamban” in Japanese, translates to “Billboard” (“signboard” in Chinese) that indicates “available capacity (to work)”. Kanban is a concept related to lean and just-in-time (JIT) production, where it is used as a scheduling system that tells you what to produce, when to produce it, and how much to produce.

Learn Kanban

Where did Kanban originate? – A Brief History on Kanban

It all started in the early 1940s. The first Kanban system was developed by Taiichi Ohno(Industrial Engineer and Businessman) for Toyota automotive in Japan. It was created as a simple planning system, the aim of which was to control and manage work and inventory at every stage of production optimally.

What is the Kanban Method?

While kanban was introduced by Taiichi Ohno in the manufacturing industry, it is David J. Anderson who was the first to apply the concept to IT, Software development and knowledge work in general in the year 2004. David built on the works by Taiichi Ohno, Eli Goldratt, Edward Demmings, Peter Drucker and others to define the Kanban Method, with concepts such as pull systems, queuing theory and flow. His first book on Kanban – “Kanban: Successfully Evolutionary Change for your Technology Business”, published in 2010, is the most comprehensive definition of the Kanban Method for knowledge work.

The Kanban Method is a process to gradually improve whatever you do – whether it is software development, IT/ Ops, Staffing, Recruitment, Marketing and Sales, Procurement etc. In fact, almost any business function can benefit from applying the principles of the Kanban Methodology.

The Kanban body of knowledge has abstracted and benefited from the works of various thought leaders since the original book was written! People such as Don Reinertsen (author of Principles of Product Development Flow), Jim Benson (pioneer of Personal Kanban) and several others.

Kanban is not a software development lifecycle methodology or an approach to project management. It requires that some process is already in place so that Kanban can be applied to incrementally change the underlying process.

David J. Anderson Tweet

Kanban Principles & Practices

4 Foundational Principles:

- Start with what you are doing now

- Agree to pursue incremental, evolutionary change

- Initially, respect current roles, responsibilities and job-titles

- Encourage acts of leadership at all levels

1. Start with what you are doing now

2. Agree to pursue incremental, evolutionary change

Kanban encourages you to make small incremental changes rather than making radical changes that might lead to resistance within the team and organization.

3. Initially, respect current roles, responsibilities and job-titles

Unlike other methods, Kanban does not impose any organizational changes by itself. So, it is not necessary to make changes to your existing roles and functions which may be performing well. The team will collaboratively identify and implement any changes needed. These three principles help the organizations overcome the typical emotional resistance and the fear of change that usually accompany any change initiatives in an organization.

4. Encourage acts of leadership at all levels

Kanban encourages continuous improvement at all the levels of the organization and it says that leadership acts don’t have to originate from senior managers only. People at all levels can provide ideas and show leadership to implement changes to continually improve the way they deliver their products and services.

“Asking people to change behavior is difficult!” –

David J. Anderson Tweet

TRIVIA – A great example of a Kanban system is used today in Tokyo Imperial Palace Gardens in Japan. The staff here uses a foolproof method to limit the flow of visitors. Each visitor receives a plastic card at the entrance, which must be returned while leaving the garden. Because the total number of cards is meaningfully limited, only so many visitors can stroll through the palace in a given time. New visitors have to wait in line till the next card/slot is available. The access to the palace is free, but it is granted only if the pre-allotted cards are available

6 Core Practices of the Kanban Method:

- Visualize the flow of work

- Limit WIP (Work in Progress)

- Manage Flow

- Make Process Policies Explicit

- Implement Feedback Loops

- Improve Collaboratively, Evolve Experimentally

1. Visualize the flow of work

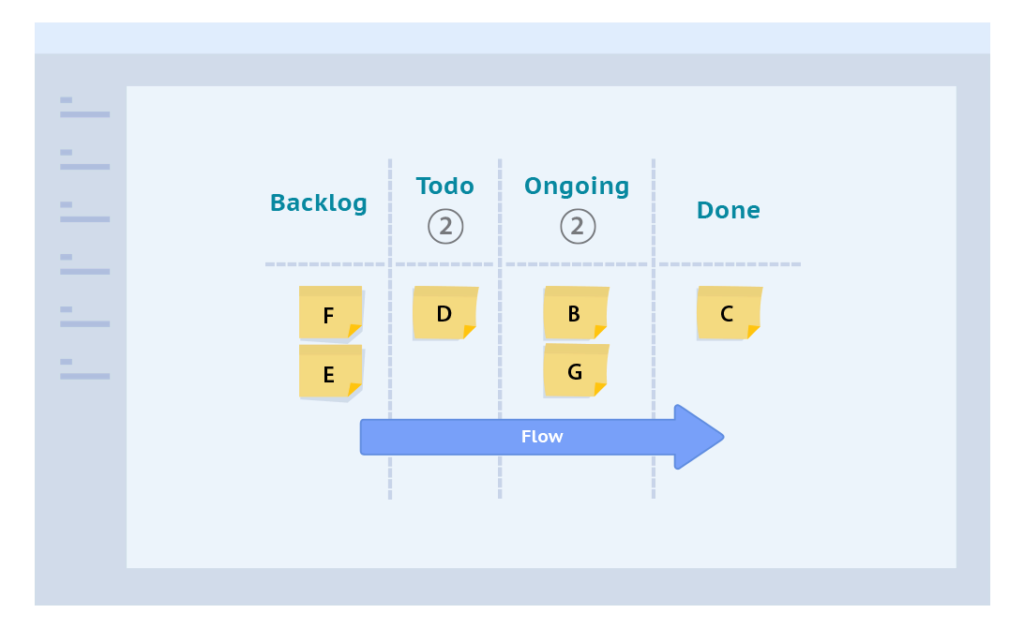

2. Limit WIP (Work in Progress)

“An interesting side effect of pull systems is that they limit work-in-progress (WIP) to some agreed-upon quantity”

David J. Anderson Tweet

3. Manage Flow

Managing and improving flow is the crux of your Kanban system after you have implemented the first 2 practices. A Kanban system helps you manage flow by highlighting the various stages of the workflow and the status of work in each stage. Depending on how well the workflow is defined and WIP Limits are set, you will observe either a smooth flow within WIP limits or work piling up as something gets held up and starts to hold up capacity. All of this affects how quickly work traverses from start to the end of the workflow (some people call it value stream). Kanban helps your team analyze the system and make adjustments to improve flow so as to reduce the time it takes to complete each piece of work.

A key aspect of this process of observing your work and resolving/ eliminating bottlenecks is to look at the intermediate wait stages (the intermediate Done stages) and see how long work items stay in these “handoff stages”. As you will learn, reducing the time spent in these wait stages is key to reducing Cycle Time. As you improve flow, your team’s delivery of work becomes smoother and more predictable. As it becomes more predictable, it becomes easier for you to make reliable commitments to your customer about when you will get done with any work you are doing for them. Improving your ability to forecast completion times reliably is a big part of implementing a Kanban system.

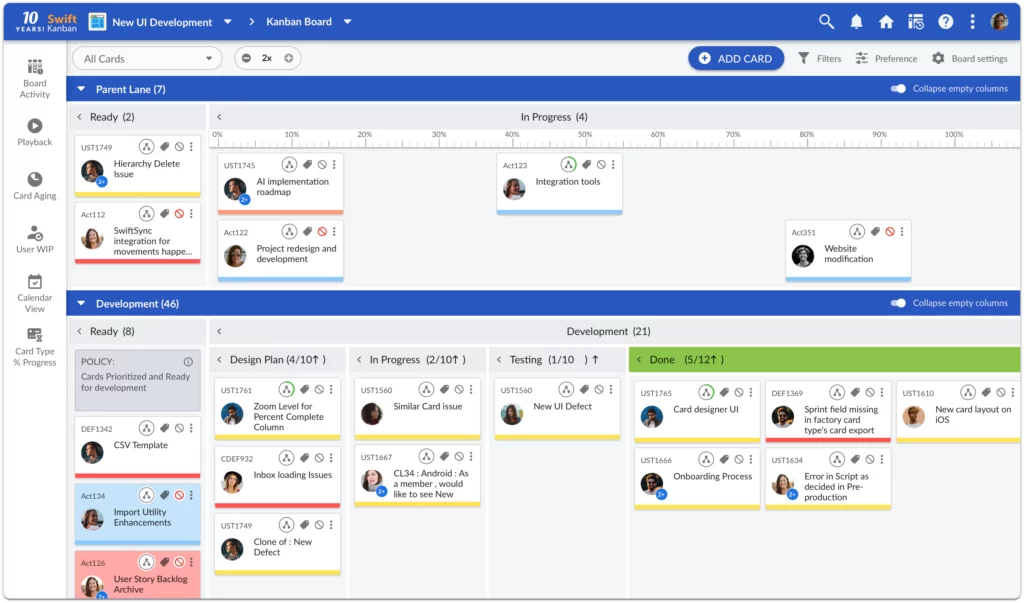

4. Make Process Policies Explicit

As part of visualizing your process, it makes sense to also define and visualize explicitly, your policies (process rules or guidelines) for how you do the work you do. By formulating explicit process guidelines, you create a common basis for all participants to understand how to do any type of work in the system. The policies can be at the board level, at a swim lane level and for each column. They can be a checklist of steps to be done for each work item-type, entry-exit criteria for each column, or anything at all that helps team members manage the flow of work on the board well. Examples of explicit policies include the definition of when a task is completed, the description of individual lanes or columns, who pulls when, etc. The policies must be defined explicitly and visualized usually on the top of the board and on each lane and column.

5. Implement Feedback Loops

6. Improve Collaboratively, Evolve Experimentally

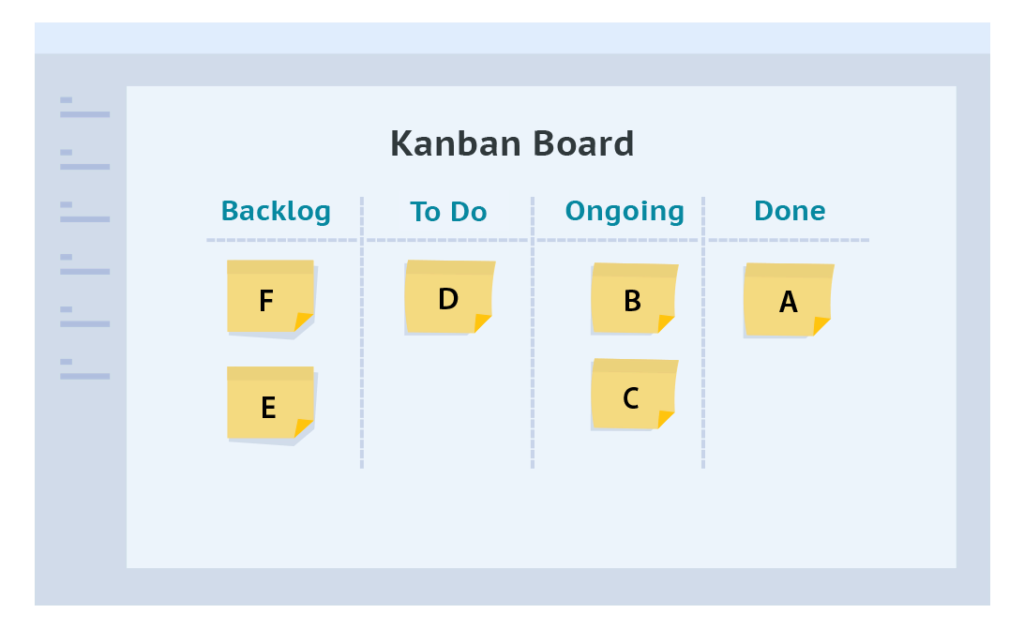

How does Kanban Work? – The Concept

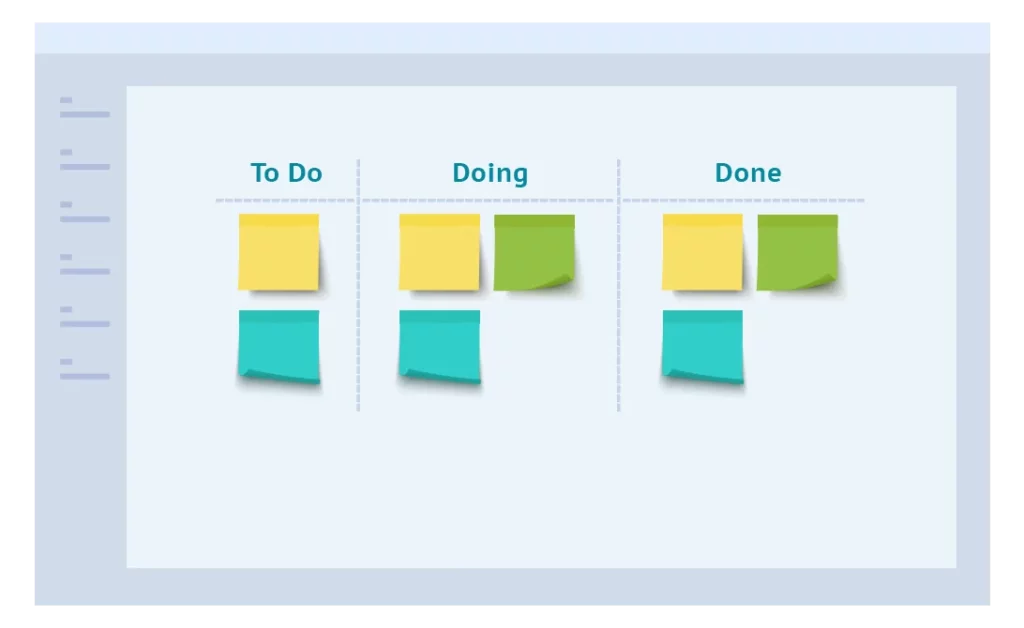

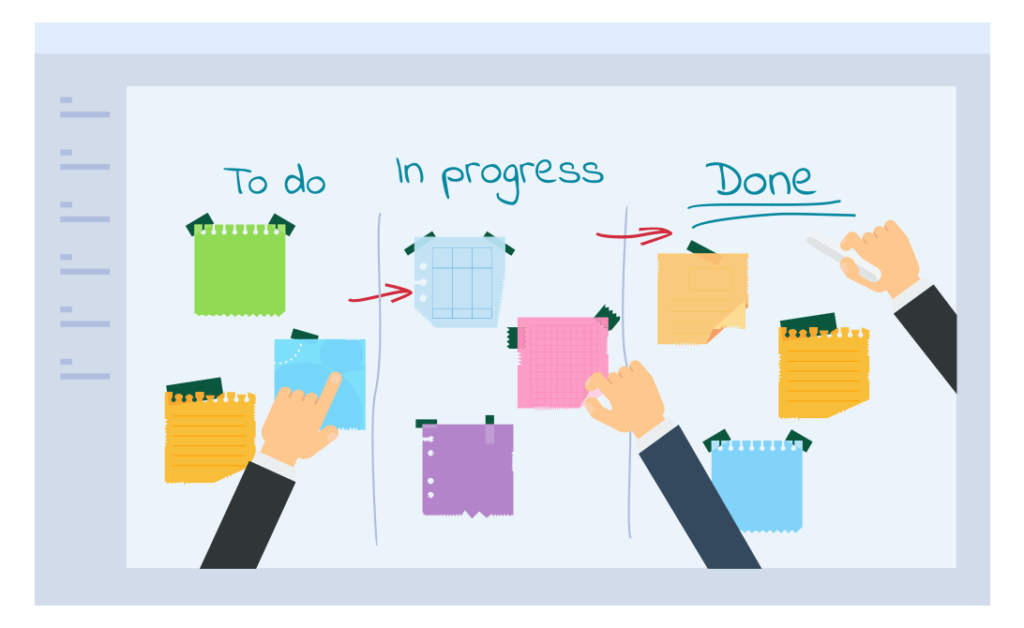

In a classic Kanban board model, there are three columns, as shown in the picture above:

👉 “Doing”: Consists of the tasks that are in progress.

👉 “Done”: Consists of the tasks that are completed.

The concept of FLOW

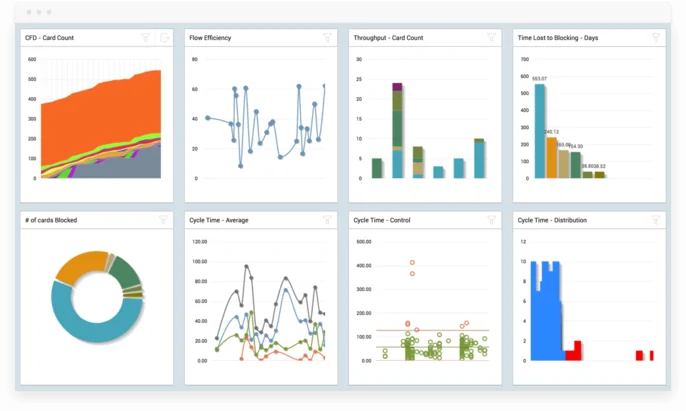

The concept of Flow is critical and by measuring Flow metrics and working to improve them, you can dramatically improve the speed of your delivery processes while reducing cycle time and improving the quality of your products or services by getting faster feedback from your customers – internal or external.

These are dealt with in great detail in the book titled “Actionable Agile” by Dan Vacanti.

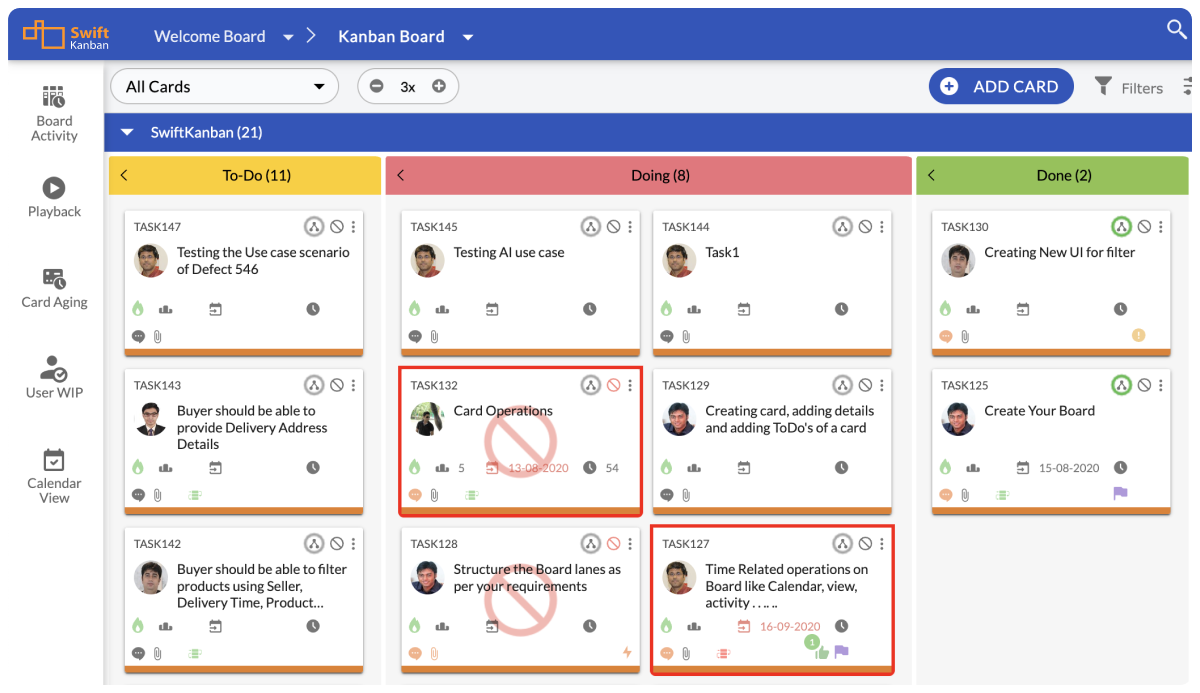

What are Kanban Cards?

A Kanban card is a physical or digital representation of a specific work item or task. It serves as a way to capture essential information about the work, such as its description, priority, who’s responsible for it, and its current status within the workflow. These cards are often used on a Kanban board, helping teams visualize and manage the progress of work items as they move through different stages of a process. The goal is to provide transparency, enabling team members to quickly understand what work needs to be done, who should do it, and where it stands in the workflow.

Kanban WIP Limits

Do not force visualization, transparency, and WIP limits on any department that does not volunteer to collaborate.” – David J. Anderson

Click To Tweet Tweet

Kanban System Examples

Kanban in IT & Software

Kanban is not a software development or a project management methodology – David makes that very clear in his ‘Blue Book’. Kanban does not say anything about how a Software should be developed. It does not even say anything about how Software projects should be planned and implemented. Therefore, Kanban is not a management framework such as Scrum. Instead, the purpose of Kanban is to continually improve one’s own work process.

Kanban was used in Microsoft’s software development operations in 2004. Since then, Kanban has been adopted enthusiastically in the IT, Ops, DevOps and applications/ software teams.

The beauty of Kanban is that it can be applied to any process or methodology. Whether you are already using Agile methods such as Scrum, XP and others, or more traditional methods – waterfall, iterative, etc. – you can apply Kanban on top of that to gradually start improving your processes, reduce cycle time and improve your flow. In the process, you will find yourself on the path to continuous delivery of features, products or services.

Kanban in Lean/ Agile software/ product development

Kanban as an Alternative Path to Enterprise Agility

Kanban beyond Software & IT

Scrum vs. Kanban

When it comes to Agile project management, two popular frameworks often come to mind: Scrum and Kanban. Both offer effective methods for managing work, but they have distinct differences that make them better suited for certain situations. Let’s explore the primary differences and help you decide which one is the right fit for your team:

Scrum

Scrum is a structured Agile framework that divides work into fixed time periods known as sprints. Each sprint typically lasts two to four weeks and involves a defined set of work items. Scrum teams hold regular planning and review meetings and daily stand-ups to manage their work. Scrum emphasizes teamwork, with roles like Product Owner, Scrum Master, and Development Team members. It offers predictability and a sense of urgency, making it ideal for projects with well-defined requirements and stable workloads.

Kanban

Kanban is a more flexible framework designed for visualizing and continuously improving workflow. Instead of time-boxed sprints, Kanban focuses on a continuous flow of work items through stages. Work is pulled when there is capacity, allowing for variability in work item sizes and priorities. Kanban boards are used to track work items’ progress. With its adaptability and a “pull” approach, Kanban is excellent for teams with variable workloads, frequent changes, and a desire to optimize workflow without drastic process changes.

The choice between Scrum and Kanban depends on your project’s nature, team dynamics, and the level of flexibility required. Consider your specific needs, and select the framework that aligns with your goals and working style.

Additional resources that might be of interest on Kanban –

You can also sign up for upcoming webinars on Kanban – or look at some great previous webinars conducted by thought-leaders such as David Anderson and several other thought leaders!

If you want to explore SwiftKanban, you can check out our rich set of features or if you’re looking for a free Kanban board signup for SwiftKanban Here!

FAQ

What does “Kanban” mean?

Who created the Kanban Method?

What is Kanban used for?

What are the four foundational principles of Kanban?

What are the six core practices of the Kanban Method?

Which industries is Kanban used in?

Author:

Visualize your workflow and manage your work in an Easy and Intuitive way.

Try our Enterprise Plan FREE for 30 days.